Quicksilver Swift to Adapt to Challenges with Mimaki Techno…

Trends in fashion are ever-evolving and unpredictable. For those companies working on the manufacturing side of these dynamic sectors, being at the forefront of the evolution and able to keep up with the rapid changes is key. Among others, dye sublimation printing technology has grown to become a must-have manufacturing tool when producing fashion. Why? Arguably, it enables users to achieve top quality with vibrant, consistent colours. It’s productive, efficient, cost-effective, easy to handle, and sustainable. To sum it up in one phrase, it ticks all the boxes.

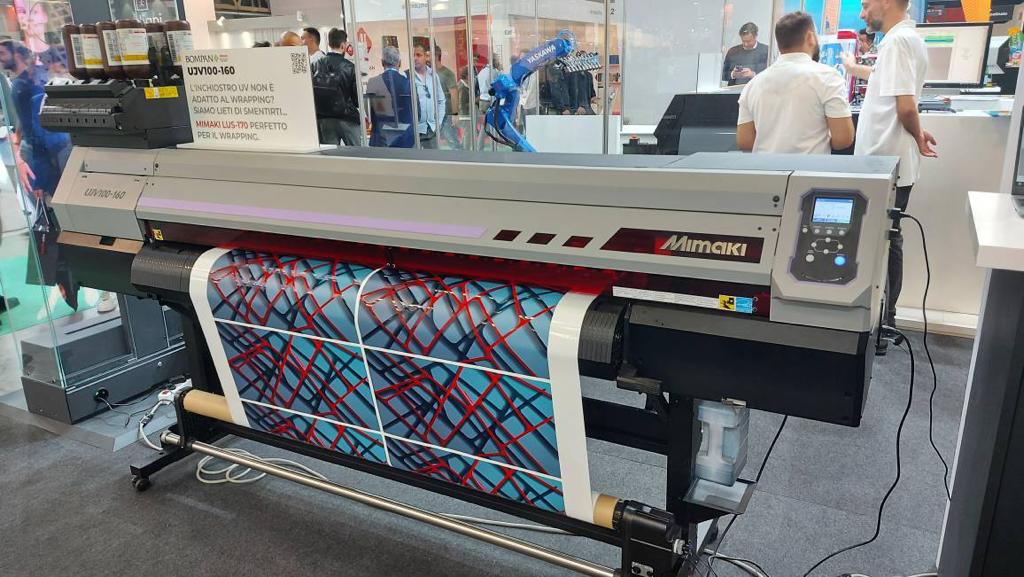

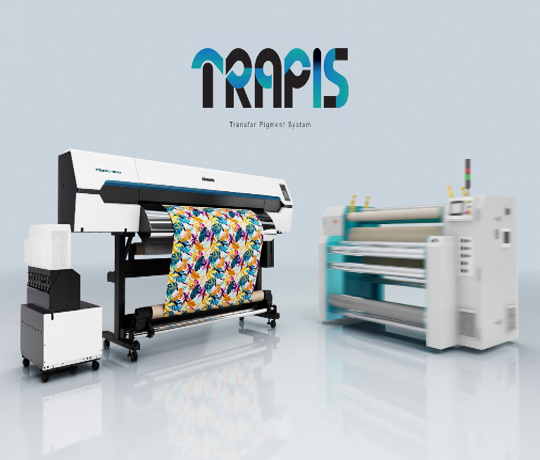

Digital sublimation printing is at the core of Italian company, Quicksilver. Specialised in manufacturing digital printed fabrics and garments for different textile market segments, the company has leveraged cutting-edge sublimation printing solutions to diversify and strengthen its production and achieve a leading market position. Quicksilver seamlessly moved from screen print transfer to inkjet transfer printing thanks to the extensive range of Mimaki technologies on offer. The company has now successfully built a healthy business, working side by side with fashion laboratories serving high-end fashion brands, as well as with premium sportswear brands. More recently, the company was faced with an increasingly competitive global market and all the changes and disruptions caused by COVID-19. To overcome the challenges, Quicksilver opted for a Mimaki Tiger-1800B MkIII, a cutting-edge industrial printer that brought in higher speeds, higher productivity, and unmatched quality, enabling the company to explore new opportunities and take the business to the next level.

Surfing inkjet sublimation printing technology

Quicksilver was established in 1987 in Padua (Italy) as a specialist in sublimation transfer through screen printing. Faced with this evolving market and the advent of inkjet technologies, the company quickly seized the opportunity and embraced the most advanced inkjet technologies to reshape and refresh the product portfolio and make its print applications more competitive and in line with market demand.

“We identified the opportunity inkjet printing posed and knew we needed to go in that direction. Mimaki was our first choice – the JV Series was known at the time to be one of the best transfer printing options in the market and already featured a wide format size compared to competitors. And that has proved to be the right move”, explains Plinio Cecchin, founder and owner of Quicksilver.

The company invested in its first Mimaki inkjet sublimation printers in 1997 through Bompan, an exclusive importer of Mimaki for Italy. Since then, Quicksilver has kept a keen focus on inkjet sublimation printing and continues to make further investments to this day, with Mimaki technologies at the forefront of its production processes. “Over the years we have explored all the options in the market and tried a few, but Mimaki remains the best choice for us. The innovations they constantly bring are perfectly in line with our needs and with the market demands.”

Quicksilver discontinued screen printing about five years ago and now focuses on inkjet printing exclusively. With the objective to become a more versatile business and explore different textile applications, Quicksilver installed the Mimaki TS500-1800, a high-volume sublimation printer, and two Mimaki TS55-1800 – with one unit equipped with 10-litre tanks. Leveraging those printers, the company was able to increase its competitive edge and customer reach through a strong, diverse product offering and improved customer service.

“Competing in the textile market is not easy for a mid-sized company. This is why selecting and choosing the right equipment was so crucial," explains Mr Cecchin. “We achieved unprecedented production efficiency in the first instance, due to the extremely comprehensive firmware from Mimaki, which provides the printing information in real time, enabling extreme efficiency and reducing risk of error. Mimaki cares about every detail, and this reflects in their product performance. This way, we have elevated our own service, which is now top quality, accurate and punctual.”

Quicksilver has now consolidated its position as a leading supplier in sportswear, fashion, high-end fashion accessories market segments, as well as in the gaming and soft signage space. Its product portfolio ranges from technical sports clothing, printed apparels and garments, printed fabrics for luxury accessories like umbrellas, printed fabrics for gaming tables and soft signage applications. Besides a diverse product portfolio, the company also offers all-round services ranging from ‘print and transfer’, the supply of sublimation printed paper rolls and the transfer process only.

The Era of the Tiger

With a wealth of products and services on offer and a strong, reputable standing in relevant markets, Quicksilver looked to take the next step to overcome the new challenges posed by the outbreak of the COVID-19 pandemic. Higher volumes were in the company’s sights, so the management went on the hunt for an industrial, robust textile sublimation printing system.

After exploring the different options available in the market, Quicksilver turned to the Mimaki Tiger-1800B MkIII and purchased a unit in May 2021 through Mimaki Bompan Textile, a joint venture between Mimaki and Bompan specialised in providing digital printing solutions for the textile and apparel market. According to Plinio Cecchin: “The ever-evolving textile printing market requires continuous investment. After the COVID-19 pandemic, the market changed dramatically and we felt the need to strengthen our competitive edge. We needed to efficiently increase the production volumes, while ensuring the high-quality standards we are known for are met. The Tiger-1800B MkIII fits all our requirements, and so did the customer service from Mimaki Bompan Textile.”

A high-speed industrial sublimation textile inkjet printer, the Tiger-1800B MkIII features Mimaki’s advanced print technology to deliver highly stable performance, market-leading print speed, and stunning print quality for both direct and transfer printing. “Not only can we achieve consistent top quality at a higher speed, but also the printer features a robust body and an advanced conveyor belt engineered to transport the transfer paper, enabling safe loading of the jumbo rolls and higher image quality and precision,” explains Mr Cecchin. “The Mimaki Tiger-1800B MkIII proved extremely cost-effective, reliable, and efficient. In fact it has allowed us to produce higher, industrial volumes and so has completely transformed our business. We estimate that we have been able to cut the energy cost due to increased production efficiency. Additionally, using 10-liter ink tanks has generated savings of up to 25% on the costs of the inks, and likewise the jumbo rolls – which are extremely efficient to load and unload – further contributing to reducing production time.”

Looking back over the past two years since the investment, Mr Cecchin adds: “Overall, the Mimaki Tiger-1800B MkIII has allowed our company to become more competitive in high-volume productions, which means that today we can address all the markets where we were not competitive in before”.

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments